Blow Molding Machine-FCP02

| Model | FCP02 |

|---|---|

| Maximum capacity (ml) | 1500 |

| Theoretical capacity (BPH) | 1800 |

| Maximum bottle size (mm) | Ø110*H330 |

| Preform tooth mouth (mm) | Ø26-Ø38 |

| Filling temperature (°C) | <49︱50-69 |

Additional files

FCP02.pdfFeatures

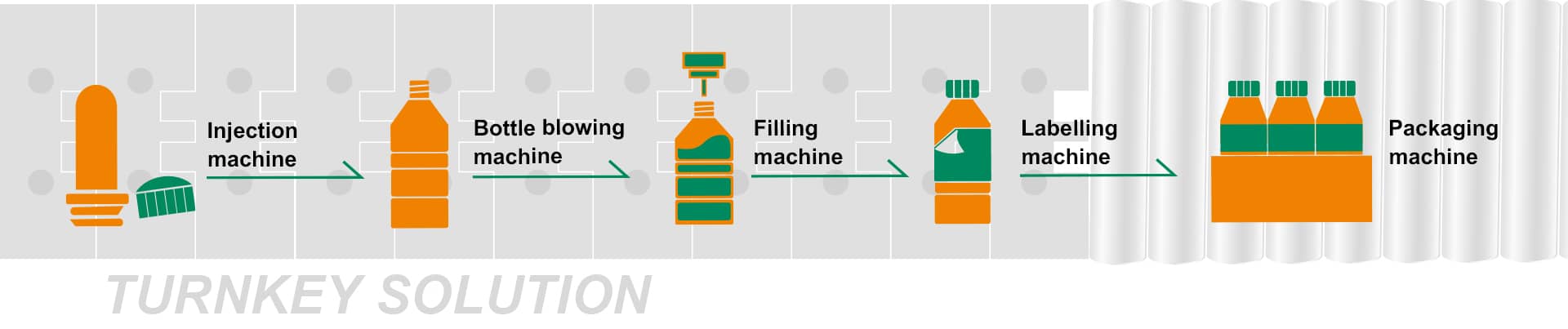

Advantage

- Grouping Brand.

- Parts Internationalization.

- Apply for Small Production Line.

- Complete Online Consultation Service.

- QR code Intelligent Management.

- Networkable Machine (Optional).

Heating

- Using continuous collective heating method.

- Neck on top, thus the preform will not be deformed after heating.

- Module design, easy to do the maintenance on lamps and cooling ducts.

Transfer

- Occupies small space, enable you to do more in the factory.

- Preforms move horizontally, no flipping, simple structure.

Forming

- Auto lubrication system, extend the life-span.

- After heating, the preforms enter the molds by grippers after the variable lead.

Blowing

- KEENPRO’s patented high pressure valve, it even attracted some valve suppliers to buy from KEENPRO.

Operation

- HMI with colourful touch screen, easy to operate.