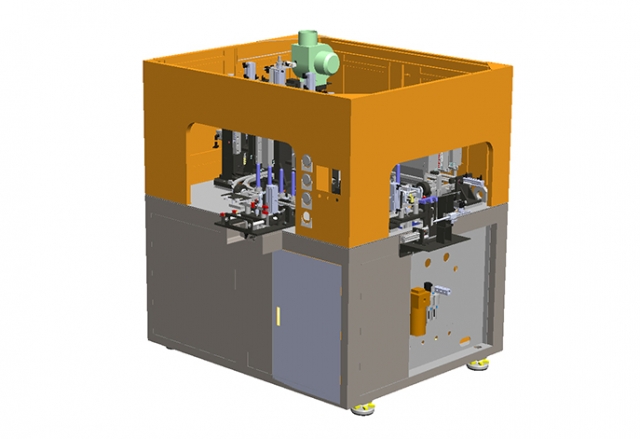

Blow Molding Machine-EM02MC

EX series blowing machine seems very simple, but yet it has its charm, and very attractive! EX series blowing machines are suitable for High-Mix Low-Volume Production. It is economical, energy-saving with high quality. You may begin with it if you have low volume productions.

| Model | EM02MC |

|---|---|

| Maximum capacity (ml) | 1500 |

| Theoretical capacity (BPH) | 2000 |

| Maximum bottle size (mm) | Ø105*H320 |

| Preform tooth mouth (mm) | Ø18-Ø55 |

| Filling temperature (°C) | <49|50-69 |

Additional files

EX.pdfFeatures

Heating Box

- “single lamp, bilateral heating”, suitable for beverage bottles, low heating power consumption, it only consumes 2kWh for every thousand bottles blown (12.5g).

- “independent lamp control”, uses for unique-shaped bottles, it makes sure the bottle wall is heated evenly.

- Every channel inside the heating box, the temperature difference is controlled within 3°C

- Modular heating box design, it gives the great convenience to do the lamps and water ducts services.

Transfer

- Servo-driven screw rod, fast movement and stable.

- U-shaped design track, special material carrier blocks with less friction, and less driving force needed.

- Composite material carrier blocks, make less dust and long-lasting life.

- Occupies small space, better for the factory arrangement.

Forming

- Servo-stretch with auto bottom detect function, it plays a very important role in the High-Mix Low Volume Production. It certainly reduces the time and labour consumption dramatically during mold changing.

Blowing

- KEENPRO’s patented high pressure valve, it even attracted some valve suppliers to buy from KEENPRO.

Operation

- HMI with colourful touch screen, easy to operate.