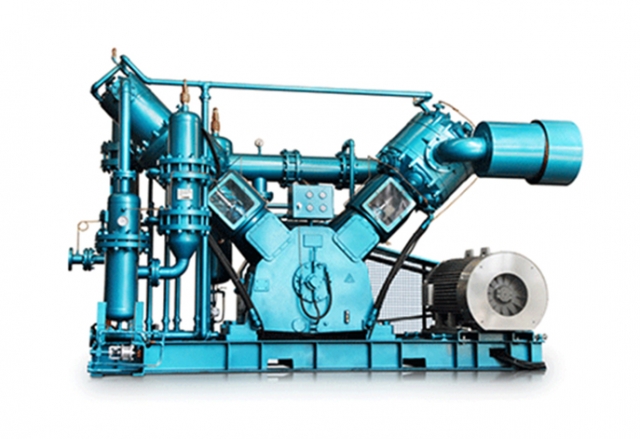

Air Compressor

| Model | kg/cm² | m³/min | HP |

|---|---|---|---|

| VFW-50 | 35 | 3.74 | 50 |

| VFW-75 | 35 | 5.61 | 75 |

| VFW-100 | 35 | 7.7 | 100 |

| VFW-125 | 35 | 9.2 | 125 |

| VFW-150 | 35 | 12.1 | 150 |

| VFW-175 | 35 | 14 | 175 |

| VFW-215 | 35 | 16.7 | 215 |

| VFW-250 | 35 | 20 | 250 |

| VFW-300 | 35 | 24 | 300 |

Features

Oil-free High Pressure Reciprocating Compressor features for PET Bottle Blowing Machine:

- High efficiency models

- Greater compression efficiency

- More air generated

- Less power bills

- Special cooling and moisture design

http://www.hsingyow.com.tw/

Characteristic

- μ - level air filtering accuracy, suitable for various industrial environments.

- Driven by the crankshaft of oil pump, no additional power needed.

- Stainless steel suction / discharge valves for high strength and long service life.

- Pistons made of aluminum alloy for effective weight reduction and dynamic balance.

- Special coating on cross-head for better wearing resistance and smoother operations in the long run.

- Single-action design for the 2nd and 3rd stages, thus reducing the number of valves needed.

- Mono-block 2nd and 3rd stage pistons, no need for 3-stage air-tight design.

- Compressor body encapsulated in a water jacket for effective cooling and increased life of parts and components.

- Piston rings made of PTFE, special formula that increases wear resistance and service life.

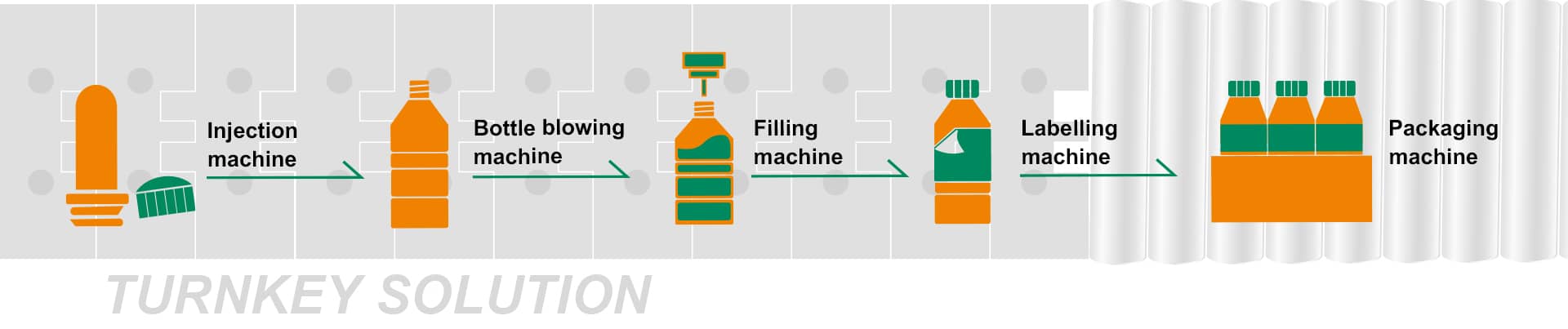

Applications of PET Bottle blowing Machine

- The demand for PET blowing is growing.

- VFW series compressors are designed exclusively for PET bottle blowing machines.

- The air compression process is 100% completely oil-free, allowing for the supply of oil-free, clean air.

- PET bottles and containers are recycled massively as the idea of environmental protection grows.