KEENPRO Perfectly Takes Advantages of Pet Material

HDPE and PET have similar material properties. They are suitable for making liquid containers such as drinking water, edible oil, beverages, sauces, and daily chemicals. They are the two most commonly compared materials among general-purpose plastics. However, HDPE has better plasticity and heat resistance than PET, but material cost and production efficiency are not as competitive as PET.

KEENPRO bottle blowing machine focuses on the PET materials. To let you know more about the production differences between HDPE and PET, we summarize the following table:

| The comparison between HDPE & PET | ||

|---|---|---|

| Material | HDPE | PET |

| Daily output | Low, only 1/10 of PET | High, 9-times higher than HDPE |

| Bottle quality | Low accuracy | High accuracy |

| Bacterial growth | easier | harder |

| Power consumption | 2-3 times higher than PET | Use only 30%-50% of HDPE |

| price | 1.5 times higher than PET | Only 65% of HDPE price |

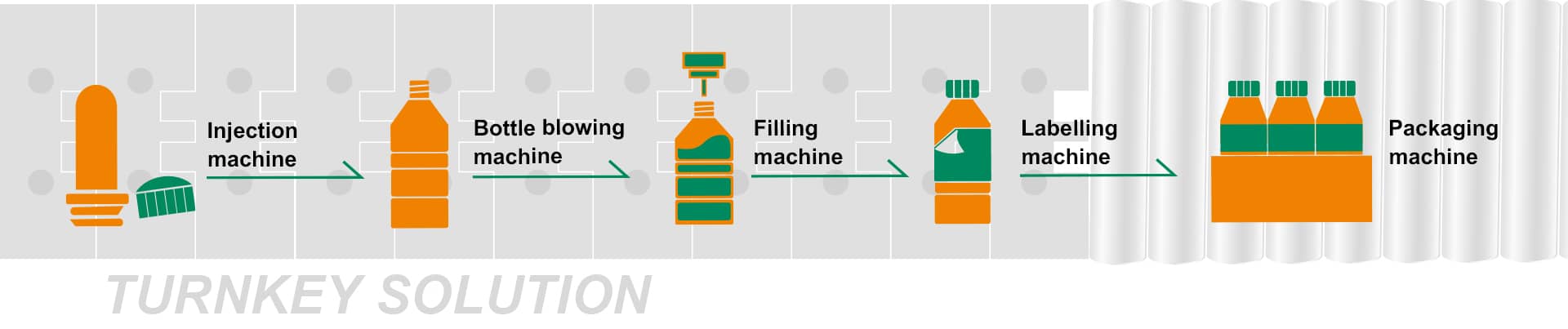

| Production line | Not suitable for connection | Connectable |

| Characteristic | Heavy; not resistance to damage | Light; resistance to damage |

It proved that the production cost of the PET is low, and the production capacity is 9-times higher than HDPE. If you have higher output demand or limited plant space, the KEENPRO Stretch blow molding machine is your best choice. We obtained patent certificates from various countries to ensure accurate and stable movements, ecofriendly. It is power-saving, compact, but more importantly, it can improve production efficiency.