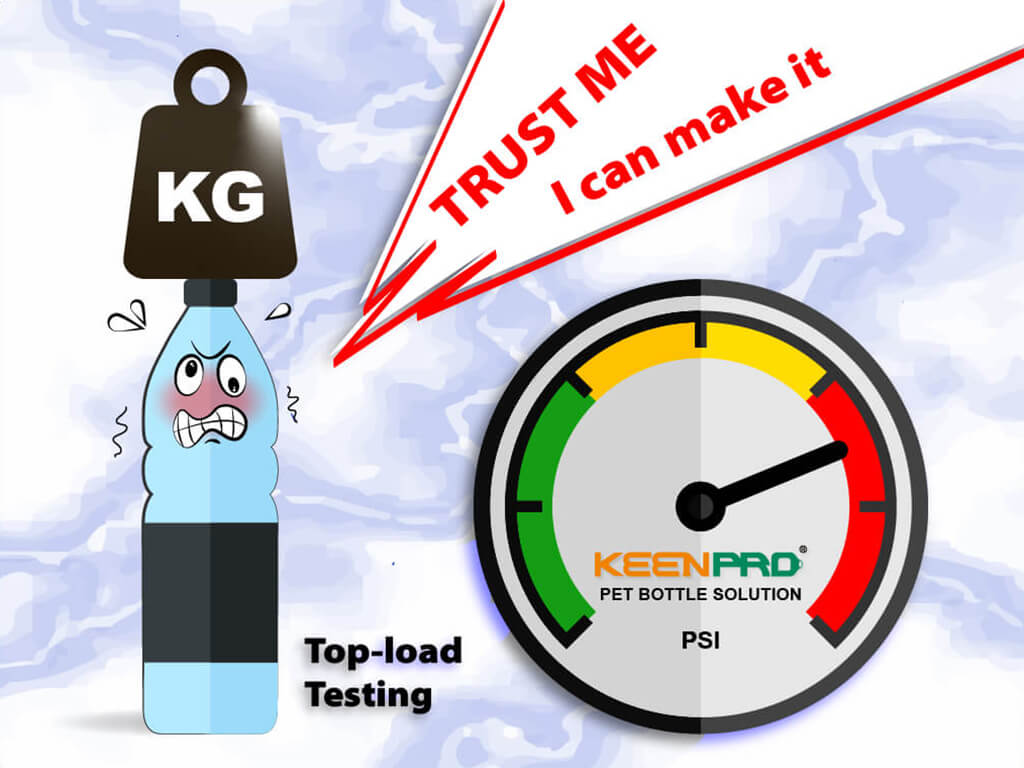

Top-load testing guarantees the quality of the bottle!

Why is Top-load testing necessary?

Because beverage container manufacturers need to ensure that the container has sufficient strength to prevent the bottle from being crushed during transportation or storage stacking. Whether it is an empty bottle or a filled bottle, it needs to be stacked or transported at some point. If the product or PET bottle is not strong enough to maintain integrity within expected standards, product leakage, breakage or deformation may occur, resulting in product return or replacement or even affecting the quality of the beverage, resulting in loss of cost and goodwill.

Top-load testing is an important test, which can ensure the proportion of bottle shape design and materials. The force applied in the test depends on the size and intended use of the bottle. Bottle manufacturers provide different test load specifications depending on the application. The test is passed if the bottle does not deform or leak when subjected to the specified load.

Top-load testing is just one of many tests performed on PET bottles. In order to ensure the quality of PET bottles, there are many quality inspection items, such as visual inspection, to check whether the appearance of PET bottles is smooth, whether there are abnormal deformations, dents, scratches or other defects. Basic size measurement, measuring the length, width, height and wall thickness of PET bottles. The uniformity of wall thickness plays a very important role in the quality of bottles. In addition, environmental impact testing, printing testing, bottle mouth sealing testing, etc. are all checks that need to be passed to ensure the quality and safety of the bottle.

The devil hides in the details, KEENPRO pays attention to every detail, and these details will become the nutrient of KEENPRO's research and development design, only to provide equipment and quality that better meet customer needs. Welcome to contact us if you have demands for our plastic bottle solutions.