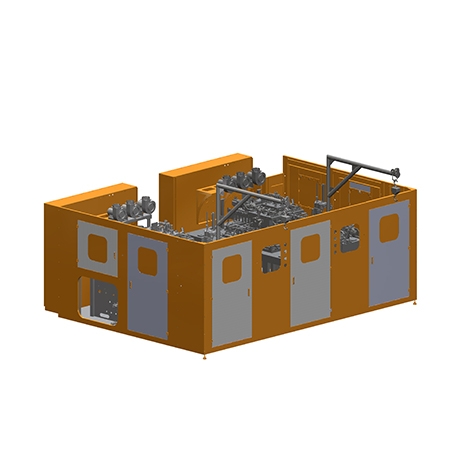

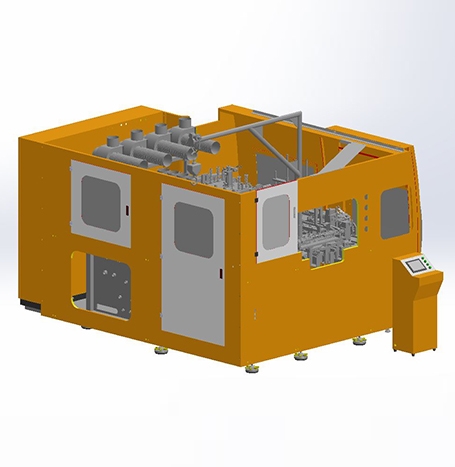

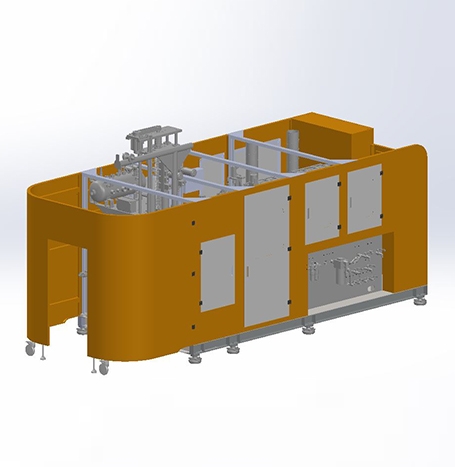

Blow Molding Machine

Blow glass, blow balloons, blow bubbles, maybe go out and get some light breeze with you~

No no no, KEENPRO does not blow those things above, but KEENPRO blow bottles, blow bottles, blow bottles!!!

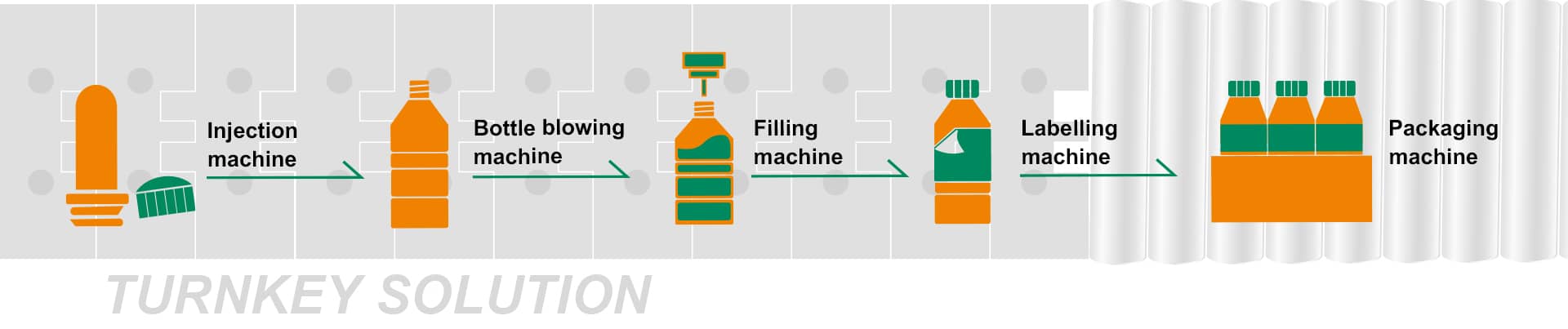

That’s right, the PET bottles which within reach in our daily lives. Any bottles you can think of, big, small, low, high, big, slim, uniquely-designed bottles.

Or the bottles you have seen before, like for water, beverage, dairy, juice, tea, oil, cosmetics, sauces.

What do we need to watch out when we choose a Blowing Machine?

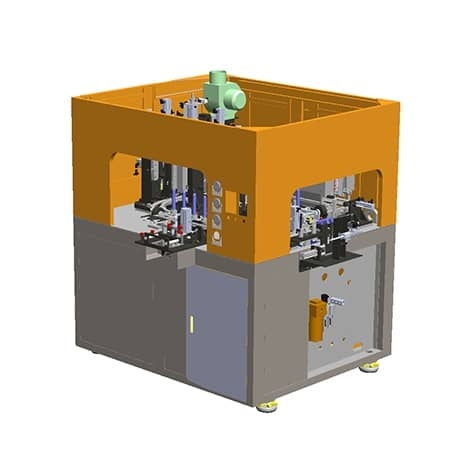

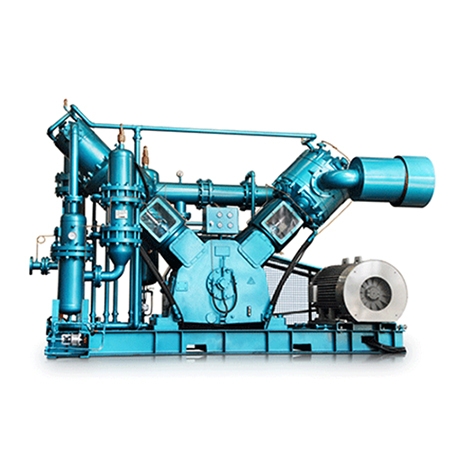

The main features of an operating blowing machine are, long continuous high temperature, continuous production, high efficiency. Thus the quality of critical components, electrical parts is very important, so are the Brands. Electrical consumption and the production rate are also extremely important, the lower energy consumption the better, and the higher production rate the better; every electrical component will get old and safety is concerned, and the mechanical parts get wear & tear, and then production rate drops, defects appear on the bottles, therefore it is necessary to have regular service and maintenance.

When choosing a Blowing Machine, not only the price matters, but also look into the production rate, the stability, blowing quality, after-sales service, the OEE….etc.

KEENPRO acquired two approvals, one is from SGS – Energy-saving Certificate and the other is MyHIJAU – Green Recognition from Malaysia.

KEENPRO’s Blowing Machine is definitely an Energy-saving and an Earth Loving Machine.

Your bottle requirement, allow KEENPRO to design for you. High energy-saving PET Blow Molding Machines from KEENPRO, they suit different demands, bottle volume between 50ml ~ 12L, production rage from 1800BPH~24000BPH to choose from. Our Machines are certified by CE, ISO and SGS.